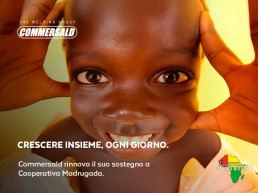

Commersald renews its commitment to a better future in Guinea-Bissau

Once again this year, we proudly renew our support for Cooperativa Madrugada, an organization that carries out vital grassroots development projects in Guinea-Bissau.

For years, we have played our small part in supporting their educational, training, and sustainable development initiatives. We do this because we believe that a company’s true impact is also measured by its commitment to building stronger, more inclusive, and supportive communities.

Every small gesture can help build a better future—one step at a time.

Together with Cooperativa Madrugada, we continue to believe in a fairer tomorrow, for everyone.

May 1st and 2nd: Labour Day break — a well-deserved one for us too

Fully operational until April 30

Closed on May 1st and 2nd

Back to work on Monday, May 5

Happy Holidays and a prosperous New Year from the entire Commersald team!

This year we faced new challenges and we succeeded. This was made possible by the dedication of our team, the trust of our clients, and the support of our partners.

Now, it’s time to take a break to return in 2025 with even greater determination!

Here are the details of our scheduled closures:

📌 Commersald S.p.A.

Closed from December 21 to January 6.

Our administration team will still be available on January 2 and 3 to handle urgent issues.

📌 Commersald Impianti

Closed from December 24 to January 1.

We wish you a peaceful holiday season and a bright 2025.

Happy Holidays and a prosperous New Year from the entire Commersald team!

ROBO700: the high-precision welding system for shaped components up to 150 kg

ROBO700 is the system developed by Commersald Impianti to meet the demands of welding shaped components weighing up to 150 kg.

Built on a single main platform, ROBO700 is equipped with:

- 7-axis Cartesian welding section: allowing for precise and stable processing of complex geometries.

- Mitsubishi CNC control: featuring ISO programming language fully integrated with welding and preheating parameters.

- User-friendly operator console and automatic torch cleaning system: ensure high operational efficiency.

High performance and consistent quality

The system’s design enables:

- Positioning of the closed powder feeder perpendicular to the torch, allowing for smooth powder flow.

- High positioning accuracy, maintained even after intensive production cycles and years of use.

- Fast and responsive movements, essential for optimizing cycle times and production flow.

- Excellent visibility of the welding area, even with safety barriers in place.

Why choose ROBO700?

- Reliability: designed to ensure continuity even during intensive production cycles.

- Consistent quality: thanks to mechanical precision and integrated process parameter control.

- Operational flexibility: ideal for companies seeking high-performance results and full process control.

For technical details or to request a consultation, contact us today.

Glasstec 2024: thank you for all your visits!

Thank you to everyone who visited us at our booth these days! It has been an important opportunity to connect, share insights, and showcase our latest advancements in PTA welding technology for the glass industry.

Your interest, questions, and feedback made this event special.

Discover the future of glass welding at Glasstec 2024

We are ready to welcome you to the international glass industry exhibition, where we will present our innovative PTA welding technology.

Thanks to its low heat input and the ability to weld complex surfaces with flawless results, this technology is perfect for the glass industry.

Some of the key benefits include:

- Optimal strength and precision, even on thin and delicate pieces.

- Minimal piece deformation.

- Reduced operating costs and improved overall performance.

If you want to discover how PTA technology can boost your performance, come visit us at Hall 13, Stand 13A03. Our consultants will be happy to show you the potential of this technology.

We look forward to seeing you!

Glasstec 2024

Are you attending Glasstec?

Discover the potential of PTA technology.

Save the date!

From October 22nd to 25th, join us at Glasstec – International Trade Fair in Düsseldorf to explore how PTA welding technology can enhance your company’s performance.

Our consultants will be waiting for you at Hall 13, Stand 13A03 to discuss it together.

Summer Break

It’s time for a break. Our offices and warehouses will be closed from August 12th to 23rd.

We will be back on Monday, August 26th, ready to carry on new projects and challenges together.

In the meantime, we wish you a great summer!

IVS fair was a success!

Participation in the 5th edition of IVS was a success!

The fair, representing one of the most important events in the Oil&Gas valve technologies and flow control industry, attracted 15,000 visitors from 69 countries, spanning all five continents.

At our booth, the interest in advanced solutions in PTA and laser cladding was extremely high.

We are grateful to all the companies that visited us, discussed their needs, and sought collaboration: we look forward to returning to you with customized projects.

- 1 to IVS: we’re waiting for you in Bergamo

🔔 Tomorrow kicks off the IVS Industrial Valve Summit in Bergamo, one of the most important events in the Oil & Gas valve technologies and flow control sector.

Our experts are ready to welcome you with advanced solutions in PTA and Laser cladding, designed to ensure high-quality welds and reliability.

Don't miss it out!

👉 Visit us at booth 98 in Hall A to discuss your specific needs and discover how our systems can enhance your production.